English ![]()

T: +86-757-81258366

E: FSHONSUN@163.COM

E: FSHONSUN@163.COM

No.1 Chuang Ye Road, Science and Technology Industrial Park , Xiqiao Town , Nanhai District , Foshan City , Guangdong Province

| Availability: | |

|---|---|

| Quantity: | |

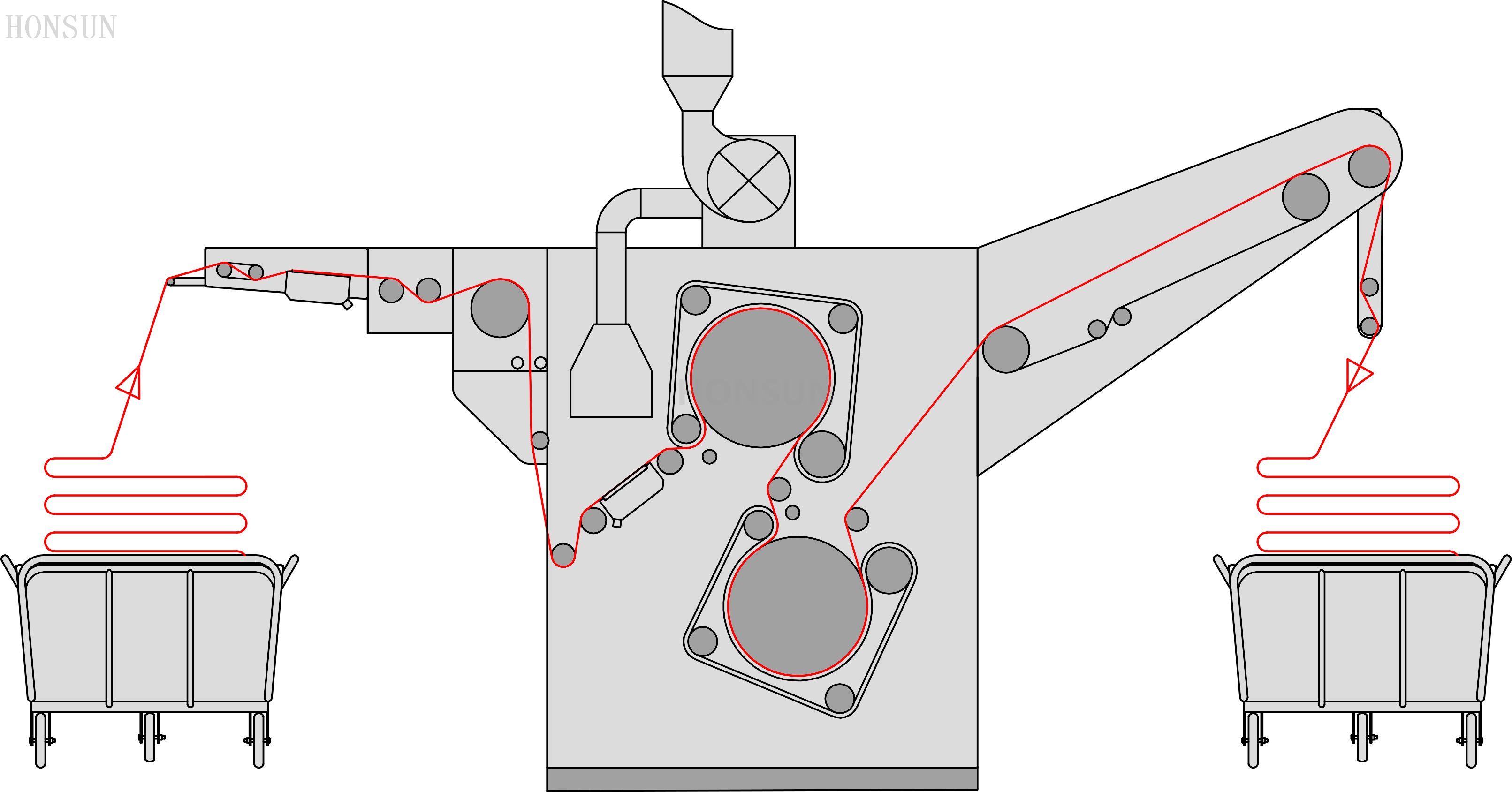

HS-CF-2400

Honsun

Use

This machine is suitable for preshrinking and setting finishing of open width pure cotton, chemical fiber, blended fabrics and knitted fabrics. The fabric treated by this machine has stable size, smooth surface, and low residual shrinkage.

Technical parameters:

• Working width: 2.4m

• Mechanical speed: 5-50 meters/minute

• Installed voltage: 3-phase 380VAC+N+PE

• Installed power: 12KW

• Heating method of drying cylinder: saturated steam

• Steam consumption:<300Kg/hour

• Steam pressure: 4 Bar saturated steam

• Compressed air: 6 Bar

• Steam tank: 2

Technical features

1. Italian ALBANY imported original woolen blankets, with two pre shrink rollers and automatic control of woolen blanket tension, ensure a longer service life of woolen blankets;

2. Siemens PLC system, 15 inch Kunlun Tongtai touch screen, Schneider frequency converter and low-voltage electrical appliances;

3. FMS tension sensor and tension amplifier imported from Switzerland with original packaging;

4. Germany's NORD new IE2 energy-saving motor and reducer (except for centering rollers and lower felt rollers);

5. Domestic high-quality Flat noodles centering device, with two expanding rollers, driven by frequency converter, whose speed can be adjusted on the touch screen;

6. 1 set of steam humidification device;

7. The lower felt expanding roller is driven by a frequency converter and its speed can be adjusted on the touch screen;

8. A cloth dropping device with a cooling conveyor belt;

9. Cloth feeding, felting, and cloth dropping are equipped with tension rollers, which can automatically control the tension of the cloth;

10. 0.35mm thick damping plate, with automatic adjustment, set manually by touch screen full digital settings or buttons.

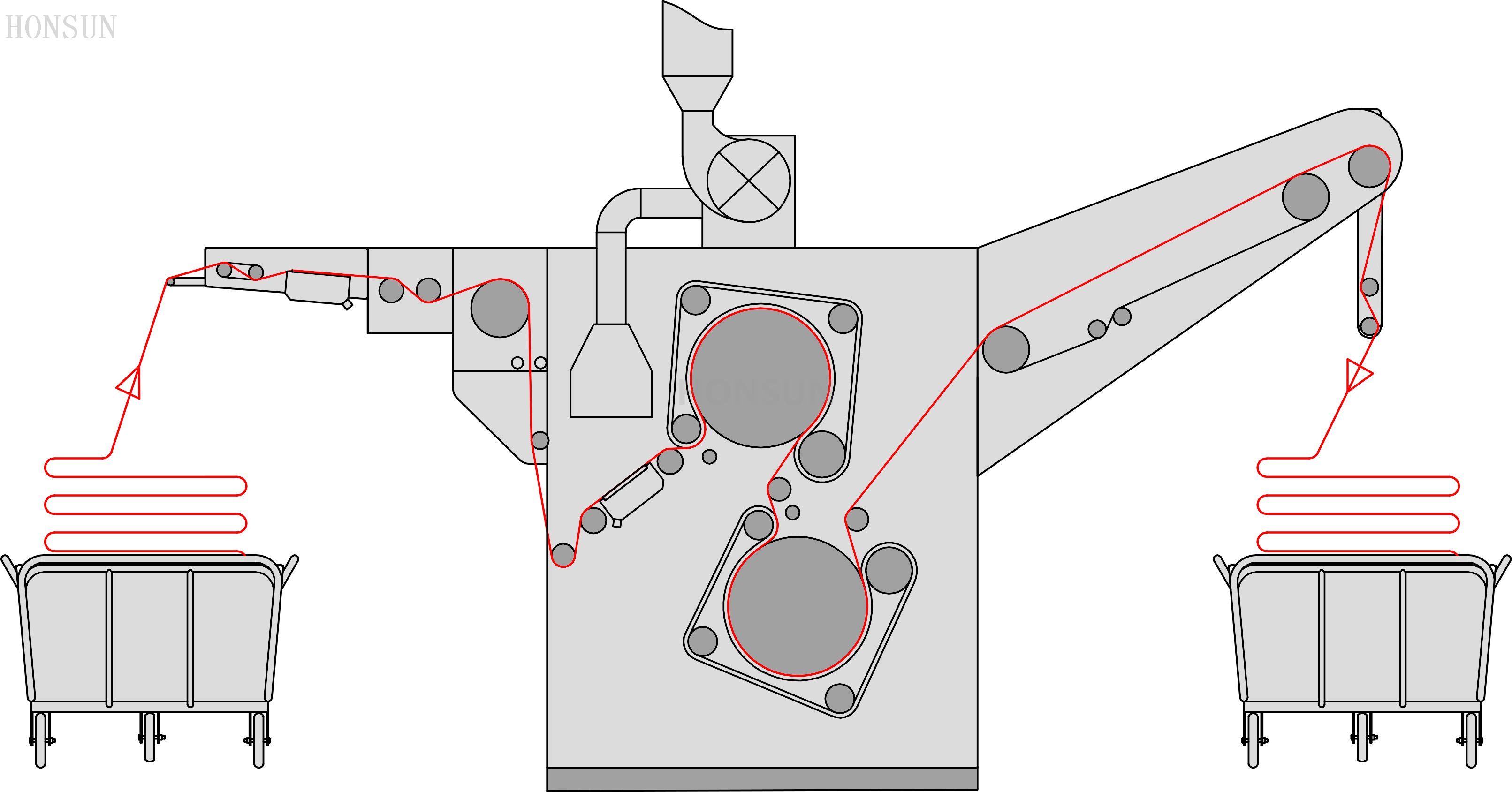

Use

This machine is suitable for preshrinking and setting finishing of open width pure cotton, chemical fiber, blended fabrics and knitted fabrics. The fabric treated by this machine has stable size, smooth surface, and low residual shrinkage.

Technical parameters:

• Working width: 2.4m

• Mechanical speed: 5-50 meters/minute

• Installed voltage: 3-phase 380VAC+N+PE

• Installed power: 12KW

• Heating method of drying cylinder: saturated steam

• Steam consumption:<300Kg/hour

• Steam pressure: 4 Bar saturated steam

• Compressed air: 6 Bar

• Steam tank: 2

Technical features

1. Italian ALBANY imported original woolen blankets, with two pre shrink rollers and automatic control of woolen blanket tension, ensure a longer service life of woolen blankets;

2. Siemens PLC system, 15 inch Kunlun Tongtai touch screen, Schneider frequency converter and low-voltage electrical appliances;

3. FMS tension sensor and tension amplifier imported from Switzerland with original packaging;

4. Germany's NORD new IE2 energy-saving motor and reducer (except for centering rollers and lower felt rollers);

5. Domestic high-quality Flat noodles centering device, with two expanding rollers, driven by frequency converter, whose speed can be adjusted on the touch screen;

6. 1 set of steam humidification device;

7. The lower felt expanding roller is driven by a frequency converter and its speed can be adjusted on the touch screen;

8. A cloth dropping device with a cooling conveyor belt;

9. Cloth feeding, felting, and cloth dropping are equipped with tension rollers, which can automatically control the tension of the cloth;

10. 0.35mm thick damping plate, with automatic adjustment, set manually by touch screen full digital settings or buttons.